|

Volunteer Railroaders

1. Everett L.

2. Jason R.

3. Angela A.

4. Andrew A.

5. Glen A.

6. Wimbley V.

7. Daniel L.

8. Cason L.

9. Issac I.

10. Carson S.

11. Chris S.

12. Toby S.

13. Kira S.

14. Ayden S.

15. Mike M.

16. David H. Sr

17. Joe S.

18. Tucker B.

19. Christian S.

20. Jim B.

Accomplishments

1. New windows installed on M4

2. M4 seats removed, repaired, and reinstalled to allow for windows and

paneling

3. First round of Planer Mill window frames wire brushed

4. Switch components recovered and assembled for installation

5. Switch assembly for third Engine House track finished

6. Final track materials to finish third Engine House track staged

7. Second guard rail installed on third Engine House track

8. Engine House Track #1 repaired

9. Train rides for Earth Day Volunteers from LSUA and for bridal party

Thank you to all of our volunteers who came out this past weekend to

make it such a great success. There was a tremendous amount of

preparation work both for physical components and planning / logistics

that contributed to the weekend being successful. If you’re reading this

and couldn’t make it out this weekend, but would like to support these

projects, please contact us today!

Friday

Before the weekend, Glen was hard at work measuring, designing,

fabricating, and painting window frames for our Fernwood, Columbia &

Gulf M4 motorcar. This past Friday was the day the M4 took a major leap

forward in terms of finishing it out completely and properly. Glen,

David, and Tucker removed the seats, installed the windows made by Glen,

and re-installed the seats further from the walls to allow for the

windows and paneling to be installed. The windows are excellent at

preserving the interior of the M4, not to mention keeping it clean on a

daily basis. Glen designed each window to fit exactly where it is,

taking into account all the nuances of each window. There is tremendous

variety from each window opening to the next. He even put trim on the

window frames so that interior paneling could be very easily measured

and installed over the edges of the frame. He also made the top of the

windows an armrest when the window is down. Simply brilliant and the M4

looks fantastic! Window opening and closing training was conducted with

the volunteers and ZEP window cleaner is the best to use on these

windows. It is recommended that museum personnel (staff & volunteers)

handle the raising & lowering of windows instead of riders.

The M4 seats are on Thomas school bus seat frames held up by two metal

legs and one wooden block. The seat side opposite the metal legs

attached directly to the school bus wall, so the wooden blocks were

installed as the other “leg.” During the course of the seat removal,

several of the wooden blocks were in terrible condition and several of

the 90 degree angle brackets on the seats were in rough shape. Glen

procured lumber and screws and David got more angle brackets to properly

repair and re-install the seats. The wooden blocks were doubled up and

fresh angle brackets went in to secure them to the floor. During the

seat disassembly, this was a good time to clean out the years of dirt

and leaves that had accumulated in between the seat cushions.

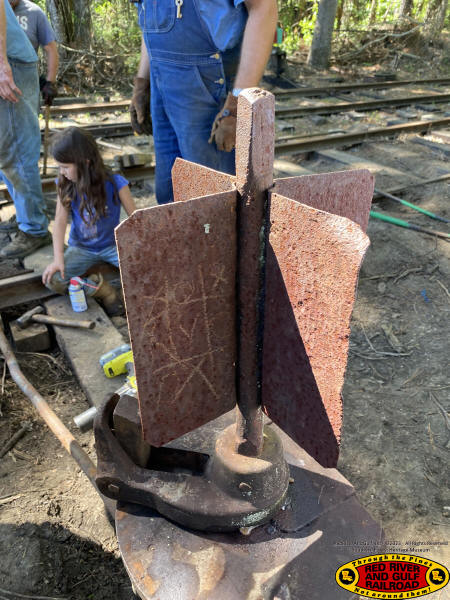

During the M4 work, Everett was hard at work recovering needed switch

parts on the sawmill pad. He used a cutoff wheel to free up transit

clips from a broken switch bar on a pair of 75 pound switch points. No

small task on 1 inch bolts! He then cleaned up the clips on the bench

grinder & wire brush and affixed them to the switch bar the Akin

brothers straightened out at the last session. As Tucker and David

worked on the M4 seats, Glen cleaned up the windows with ZEP window

cleaner. The windows were so clear, you could hardly see a window there

at all!

Saturday

After the morning briefing, the volunteers split into several groups. Up

at the Engine House, the remainder of the M4 seats were re-installed by

Glen, David, Jason, Andrew, Ayden, and Tucker. With the seats in place,

Jason and Ayden brought M4 down to the Commissary Depot for the day.

Glen, Andrew, David, and Tucker then started bringing up the final

sticks of rail from the Sawmill pad for the third Engine House track.

At the Finished Lumber Shed, Mike taught Wimbley, Daniel, and Cason,

later joined by Isaac, how he wanted the Planer Mill window frames wire

brushed. These are the original window frames from the Planer Mill, the

oldest building on the museum complex. Mike has engineered a system to

retrieve them from the mill and to lower them down. That way, the frame

repair and repaint can be done in a small shop format inside the lumber

shed. Mike is taking down several at a time that will be wire brushed,

repaired, painted, and then re-installed before the next group of

windows come out. Many window panes are missing, so new panes are going

in to protect and preserve this historic building.

The Planer Mill windows are a major priority project at the museum this

year, requiring financing and time. If you can assist, please contact us

today. Any and all help is needed.

Christian Singletary, the museum intern from LSUA, organized and led an

Earth Day of Service at the museum, which marshaled many students and

professors from LSUA in various projects at the museum. They cleaned up

the Resilient Forest Nature Trail which had numerous blown-down trees

from past storms and hurricanes. They also went around with soap water

buckets and rags and gave all the museum information signs a good clean.

With their day of service complete, Jason, Wimbley, and Carson gave the

volunteers a ride around the loop aboard M4. After that, many of the

volunteers came up to visit and see our ongoing railroad work. It was a

great opportunity for all the parties that helped make the LSUA

internship at the museum successful to meet, interact, and to enjoy time

together.

During the course of the day, the museum had numerous visitors. Angela,

Kira, and Toby helped shuttle visitors on the golf cart and to provide

informational tours.

In the mid-morning, with the frames wire brushed, the M4 at the Depot,

and the morning to-dos completed, the whole crew fell in to finish

installing the switch assembly for Engine House Track #3 and finishing

the turnout. Everett, Joe, David, Jason, Ayden, Andrew, Wimbley, Cason,

Isaac, Daniel, Glen, and Tucker worked all day to install the switch

assembly and to finish the turnout. The closure rails were joined

together up to the points, the stock rail was unspiked and swung out,

ties were adjusted for the stock rail, a tie removed to make room for

the switch tie, the switch tie installed, the switch bar installed, a

switch stand brought over from the sawmill pad, and everything connected

together. This was just plain hard work with tongs, shovels, picks,

wrenches, claw bars, lining bars, grinders, cut off wheels, bolts, nuts,

washers, ties, rail, joint bars, chains, the tractor, and plenty of

sweat. Everett and Ayden put together the switch bar with transit clips

and secured them to the switch points. Everett, Ayden, and Angela were

also rounding up nuts and bolts for the switch bar assembly and track

bolts, nuts, and washers throughout the day. Joe and David disassembled

the switch stand to free it up while Tucker cleaned the switch housing

plate and bolts on the bench wire brush. Jason, Andrew, and Joe muscled

the switch stand in place and then secured the bars to the stand.

Everett and Glen were constantly moving about drilling holes for spikes

at the switch stand and on numerous ties as the whole crew alternated

spiking rail down and spiking the switch stand down.

The final task was to cut a piece of rail to make the final length of

one of the closure rails. David inserted two flat washers into the rail

saw arbor to secure the cutting wheel more snugly in the saw. David got

the cut started, but two discs were broken in the process. A very

vigorous discussion ensued on the size and thickness of rail saw discs.

A third disc was put on and Joe found the magic touch on the saw. He

finished the cut smoothly, with one wheel, and earned his spot for a

“job well done!” Chris provided some advice on the saw as well and

joined the discussion with Everett, David, and Joe.

As Jason, Wimbley, and Carson headed down to the Commissary, the

volunteers back at the switch installed the last length of rail, now cut

to the right length, and finished the switch assembly. Down at the

Commissary, with the bridal party aboard the M4, now adorned with great

windows, with time to kill, the crew took two laps around the main loop.

The whole group greatly enjoyed it, for we could see the bridal party

having a grand ol’ time on the second lap, waving and cheering as they

went by!

During these runs, the rail head was ground down at one joint for a

smooth meet and Everett worked on the other rail meet that needed

grinding on Sunday. Everett also grabbed the red and green paint, and

after knocking off the rust, painted the switch target for the upcoming

test. The big test came when the M4 crew returned the Doodlebug back to

the Engine House. Jason backed the M4 slowly over the newly completed

switch assembly as the whole crew watched closely. When he gently parked

M4 in the Engine House, all were glad to see the hard day’s work pay

off. As the day wound down, the crew gathered for a celebratory picture

on this occasion. The switch stand throws very smoothly and the switch

is complete. For the first time since 1954, there are four switch stands

north of the Engine House.

After the M4 rolled into the Engine House, Joe and Chris noticed a crack

on the switch stand on the track-side leg. The switch stand held up

fine, but they put together a plan to nickel weld the crack on the cast

iron stack, a future task that will take this switch project from good

to great.

During the late afternoon, Joseph Jr. found broken pieces of the

builders plate for Meridian Clyde Skidder builders #310. It was found

just behind the new switch stand past a few pine trees in the dirt where

the old Ford pickup truck had rested for many years. Joe found an

additional piece on Sunday. These pieces are an electrolysis bath

getting much of the corrosion off and preparing them for an exhibit in

the Commissary. Even today new and interesting artifacts are discovered

or “re-discovered” at Long Leaf.

With the cutting and hammer swinging, and several tools such as the rail

saw put up, several of the younger volunteers, such as Joe Jr and

Karleigh, were able to get involved turning wrenches on track bolts at

the joint bars. A small step in a big way to allow for positive

contributions by all involved.

Sunday

With a sprinkling of rain, the crew of Glen, Wimbley, Everett, Jason,

David, Joe, Andrew, Angela, Ayden, Toby, Kira, and Tucker delved in to

finish the switch turnout. Glen brought his cutting torch to cut the

needed bolt holes on several pieces of rail. With the holes cut, the

final bolts were secured to the joint bars. David and Joe used the

tractor to bring in two more lengths of rail and to push out a stick of

rail with a bad bend in it. The final joint securing for the turnout was

then completed with several joints put together. Ayden, Kira, and Andrew

drug over the good tie taken out the day before. This tie was inserted

to help support the switch turnout after digging out a tie space.

The second guard rail was then positioned into place. Glen cut the bolt

holes on the rail to secure the guard rail while Everett and Ayden cut

pipe for spacers between the guard rail and the stock rail. With the

guard rail secured, Jason, Joe, Tucker, David, Wimbley, Andrew, and Glen

positioned the rail for gauging and spiking on the May 6th weekend.

Everett, Angela, Wimbley, and Ayden, while the rail was being positioned

on track 3, went to work on track #1 to fix a wide spot and a narrow

spot near the switch frog. The dirt was cleared away and additional

spikes hammered down to correct the wide spot. A positive gauge bar was

installed at the narrow spot as well. This will correct the flange

squealing and issues equipment has had coming in and out of track #1.

With major successes complete, the volunteers shook hands, said

goodbyes, made plans for the next sessions, cleaned up at the lodge, ate

a quick bite, and made the road for home as the sun peeked from behind

the clouds and made for a beautiful Louisiana day.

-Tucker "Who Dat" Baker

RR&G Road Master

|

.jpg)

.jpg)

.jpg)

.jpg)