|

|

|

Work Session October 8, 2022

To join the fun, contact the railroad at: Work-Session @ RedRiverAndGulf.net (no spaces)

|

|

Volunteer

Railroaders

Everett, David, Jason and Noah

started working on Friday with many projects. Everett repaired the

thermostat in Bunkhouse Room #3. The thermostat eventually had to be

replaced and the volunteers furnished a new one. David and Jason

finished cutting up the sweet gum tree that Larry had taken down to

create more light in the Planer Mill parking lot. Saturday

The volunteers met up at the lodge

kitchen for Saturday’s objectives and then split into various teams.

Mike continued his work on getting more electrical lines and lighting at

the take down shed ready for the upcoming fall festival. This will give

more lighting for this area at night as this will be the main parking

area for the festival.

On Sunday, Jason, Joe, Everett, and

Mike continued the air horn system installation. Mike reviewed the

schematics and setup with them. Everett made multiple runs into

Alexandria to pick up more parts and supplies to get the job done. They

got the horn setup on the motorman’s exterior side, ran the air line

down to the compressor and air reservoir, installed the wiring for the

compressor, and added a gauge and switch on the control panel for the

compressor. Jason put together a short video from the weekend of the M4

in service and with the new air horn. The horn sounds great and this is

a great improvement!

Monday Everett cleaned the Museum's "Limousine” golf cart and had it looking fantastic. He also cleaned, ground, and refaced over 100 spikes, as our good spike supply is running short. We still have more than 200 left to clean and prep that we’ve recovered from various track maintenance efforts.

Tuesday

On Tuesday, Everett replaced 4 more

sets of splice bars with joint bars, two going up hill from Long Leaf

Road and two coming down toward the Planer Mill. He spent several hours

working on the 90 pound-60 pound joint on the hill trying to raise the

60 pound rail without success as it is at least a two man job. The

remainder of the work coming down hill toward the Planer Mill is also a

two man job. After completing what he could do on the joint bars,

Everett ground on the rail joints where two different sizes meet to

smooth out the ride and cut the risks of derailment at those joints. He

started first on the down hill to the Planer Mill area. Wednesday Everett worked more on the big hill grinding rail joint meets smooth and then more again around the loop. He has continually identified the rail joint meets needing attention and grind them down to a smoother meet

Thursday

Mike Miller, Everett, and David

teamed up to finish up work on the main loop track going up the hill.

They lifted the outside on one section and re-spiked it to fix the

super-elevation issue. This re-aligned the rail at the 90-60 pound

joint. Thursday afternoon, Everett walked the loop and did a final

inspection. He made caution and proceed boards where super-elevation

work will be needed over the winter.

-Tucker "Who Dat" Baker

|

|

|

|

Short video of M4 on the move and getting a new air horn

|

|

Friday |

|

|

|

New RR&G Member Patches

|

|

|

|

It is very dry at Long Leaf, so prior to grinding and drilling rail, Noah filled up the weed-sprayer so that we could combat any fire we started. There were no fires this day.

|

|

|

|

Everett, David, Jason & Noah spent the day working on "the hill" and near Lueck's Loft at the top.

|

|

|

|

Removing old splice bars and replacing them with joint bars.

|

|

|

|

C&P M8

|

|

|

|

|

|

|

|

Noah takes a turn at driving a spike

|

|

|

|

|

|

|

|

Grinding off bolts too rusted to be removed

|

|

|

|

|

|

Saturday |

|

|

|

Saturday morning safety brief with Tucker at the Lodge

|

|

|

|

Jason cut up and removed a fallen try on the Car Shop Lead

|

|

|

|

Cleaned and washed SFHM "Limo"

|

|

|

|

Joe relocates the Insley's dredge

|

|

|

|

Clearing brush at the Engine House

|

|

|

|

Work crew clearing brush between the Engine House and Runaway Crossing

|

|

|

|

|

|

|

|

Group inspection of M4's undercarriage... trying to locate a good spot to install the air compressor and tank for the new horn.

|

|

|

|

The guys took off the grill and removed an old horn. They also removed the old horn from above the Motorman's seat.

|

|

|

|

David tests the torch

|

|

|

|

|

|

|

|

|

|

|

|

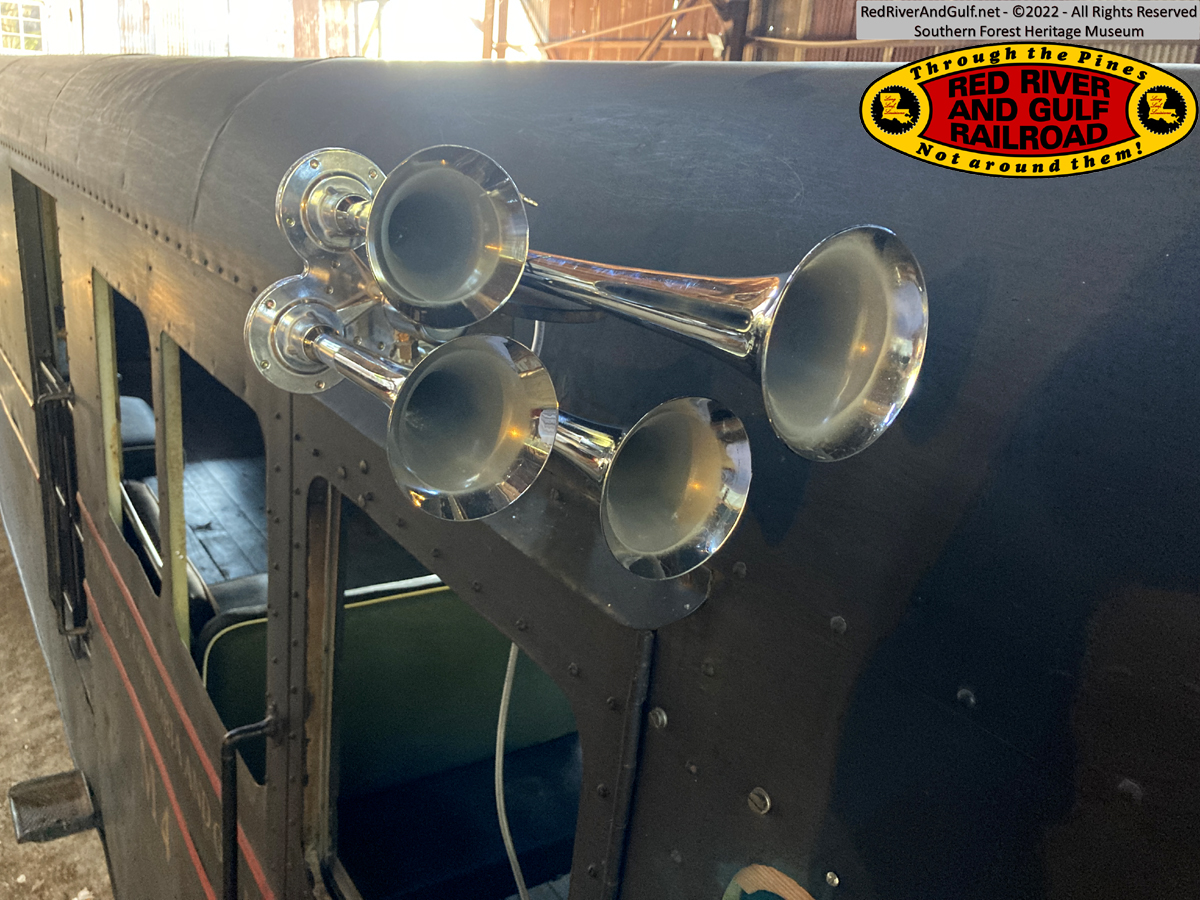

Joe fits the new horn assembly

|

|

|

|

The guys cleaned off several years of brush from atop #400

|

|

Sunday |

|

|

|

Just a neat shot of a rural Louisiana railroad crossing. In this case the road is Long Leaf Road near the Engine House.

|

|

|

|

Mike & Everett work on the wiring for the new air horn

|

|

|

|

Joe & Mike continue working on the air horn

|

|

|

|

M4's new voice

|

|

|

|

Jason & Joe mounted the compressor, tank, relay, and all the hoses and wires under the M4.

|

|

Tank and compressor mounted under M4

|

|

|

|

Joe fits the air gauge in the dash. M4 also got a new switch to control power to the compressor. The old air horn button was reused.

|