|

|

|

Work Session April 9, 2022

To join the fun, contact the railroad at: Work-Session @ RedRiverAndGulf.net (no spaces)

|

|

Volunteer

Railroaders: - Transported M-22 to Long Leaf - Unloaded M-22 - Initial cleaning of M-22 - Initial repairs to M-22 returned her to service - Emergency Track Repairs - Vertical Drilling Mill returned to service for first time since 1969

- Back-up light on M-2

repaired

Friday

Saturday

-Everett Lueck

|

|

Video of M-22 |

|

|

|

Friday |

|

|

|

The Akin brothers depart Shreveport with M-22

|

|

Keeping a close eye on the RR&G's newest motive power.

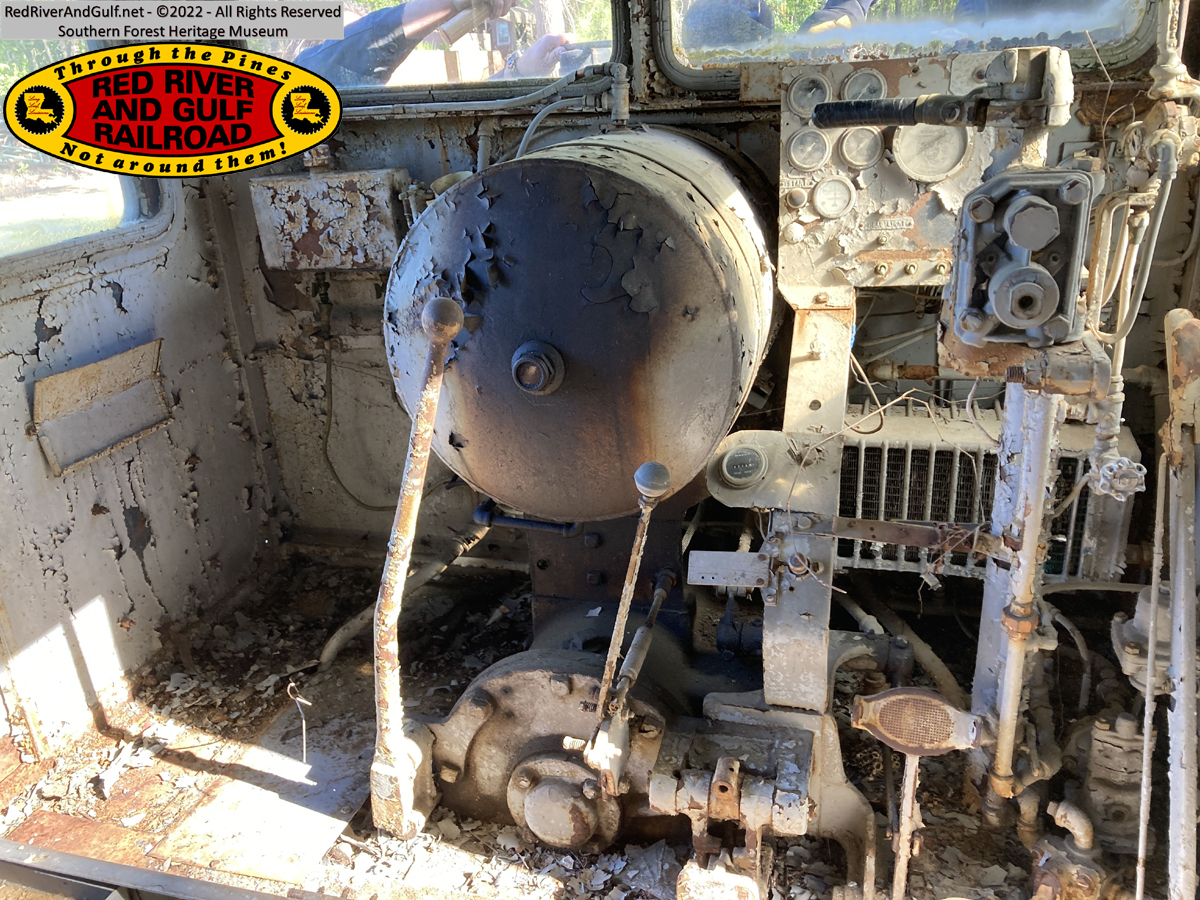

Photo Essay of the Guts of M-22

|

|

Saturday |

|

|

|

Backing to the Engine House

|

|

|

|

|

|

|

|

Casey ably backs the rig to the Engine House

|

|

|

|

|

|

|

|

|

|

|

|

An artsy shot

|

|

|

|

The sun is rising on a new day... and a new life... for this ol' critter.

|

|

|

|

The brothers jack-knifed the trailer onto Track #2 on the first attempt, lining up on the rails perfectly. It was an impressive display of professionalism.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Up she goes

|

|

|

|

|

|

|

|

Cody directs Casey

|

|

|

|

Done

|

|

|

|

Down she goes

|

|

|

|

TOUCHDOWN!

|

|

|

|

A little help from the volunteers got both axels onto RR&G rails

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The guys store their gear before moving the truck.

|

|

|

|

Everett oils the Engineer's side door track so we could get it fully open.

|

|

|

|

Wimbley oiled the Fireman's side

|

|

|

|

|

|

|

|

Ladies, Cody is single.

|

|

|

|

Starting the clean-up

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gavin & David replace a switch handle

|

|

|

|

Jacques begins the power washing

|

|

|

|

Joe takes it to the next level.

|

|

|

|

Jason and his crew (Gavin, Joe Jr, and Noah) walked the entire loop to hammer down lose spikes and locate problem areas. We also labeled all of the switch stands, installed switch locks where needed, and inspected and oiled existing switch locks.

|

|

|

|

Planer Mill Jct - Switch #2

|

|

|

|

During the track inspection tour, 2 trouble spots were located. The most critical was between the Commissary/Depot and Long Leaf Road. The track was heavily damaged by a tracked vehicle of some sort. We don't know how it happened, but we don't believe any SFHM or RR&G personnel did it. In any case, all hands were enlisted to repair the area so the M-4 could safely operate.

|

|

|

|

Staging replacement ties

|

|

|

|

Glen digs out old ties

|

|

|

|

Glen has saved us many MANY hours of hard work with his tractor.

|

|

|

|

|

|

|

|

Lifting a tie so it can be cribbed and spiked.

|

|

|

|

Joe adjusts the gauge.

|

|

|

|

|

|

|

|

Mike brings in rock ballast

|

|

|

|

|

|

|

|

Wimbley & Clint spread the ballast.

|

|

|

|

Glen shoves in new ties

|

|

|

|

The Akin/Hearne team worked on the M-22 until she was purring once again!

According to David: "The patient wouldn't respond, so myself and Casey & Cody, had to perform open heart surgery on it to resurrect her. Opened the access panel on top of the hood, then removed the valve cover, then after several phone calls to the specialist in Detroit Diesels (my son, David Jr.) we discovered two of the three fuel injectors were frozen. After removing these, they were freed up on the operating table (shop bench) and restored to full function. Once everything was back in place, patient came to life immediately after hittin' the starter. A good time was had by all taking turns running it up and down the Engine House track."

|

|

|

|

Gavin takes a turn at the controls under Casey's tutelage while Noah guards against a zombie attack.

|

|

|

|

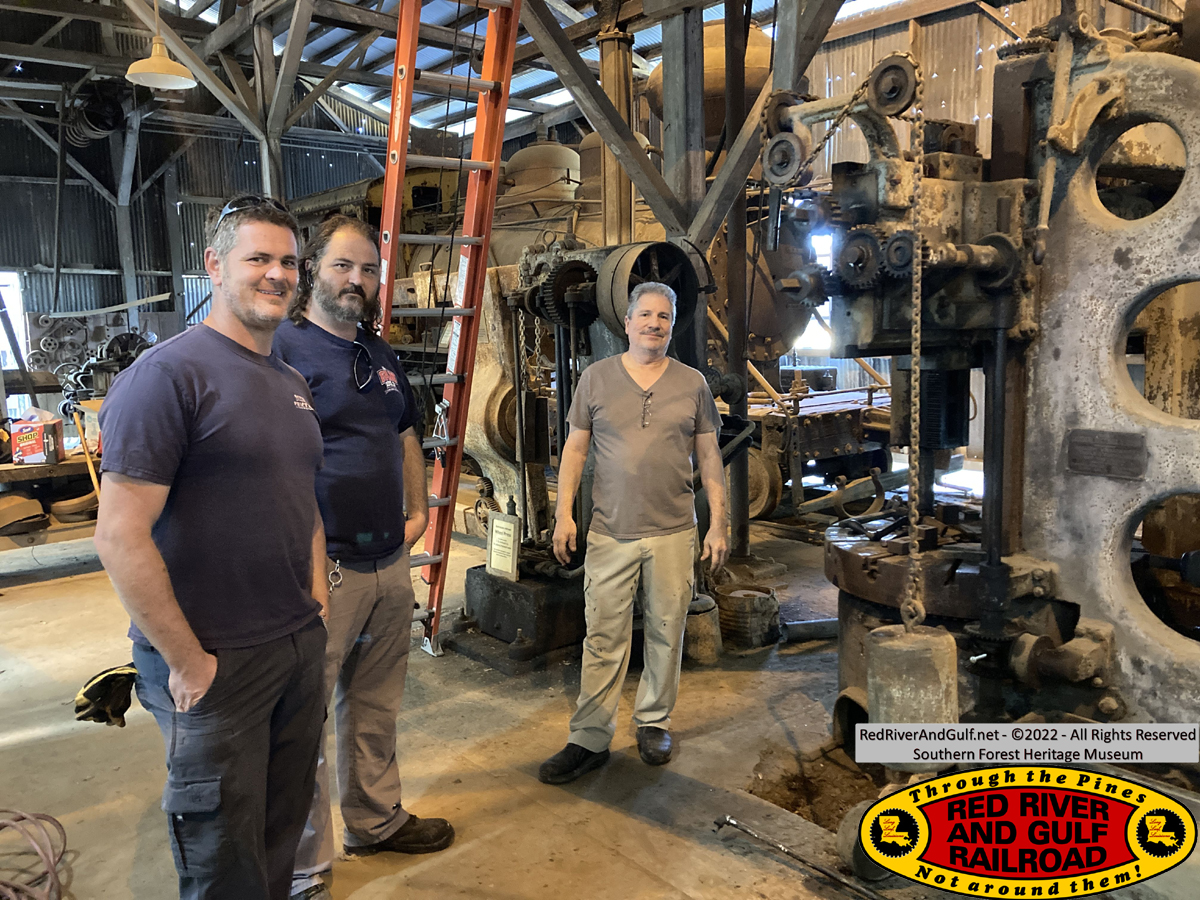

Cody & Casey stand with Glen just after Glen & Mike returned the Vertical Boring Mill to service for first time since 1969.

|

|

|

|

|

|

|

|

The SFHM Tractor

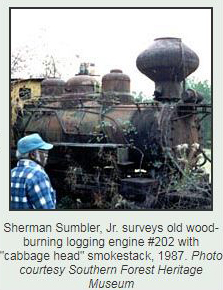

Saturday evening, after dinner, the wedding party that rented the museum was under full swing. The security guard, Gary, frequently came by the lodge to chat with the RR&G volunteers and escape the wedding crowd and noise. His company was appreciated by all of us. During one of the exchanges, Everett mentioned knowing Draughon Crowell personally (the last Crowell to manage the mill) and one of his best friends, Sherman Sumbler. When Mr. Sumbler's name was mentioned, Gary put his hand on Everett's chest and quietly inquired "You knew my Daddy?" He said it with such sincere reverence and emotion that we were all a bit choked up. Everett immediately asked Gary (whom he's know for years) "Your last name is Sumbler!? I had no idea!" What followed were many colorful stories about the Sumbler family that we all appreciated hearing. Sherman worked in the mill up to the time it was shut down and remained an employee of the Crowell family for quite a long time after that. Gary was BORN in Long Leaf and lived his first 10 years here until the mill was shut down.

It was quite a conversation and will be long remembered by all those present.

The tractor above bears the name Sherman Sumbler Jr. If you've ever wondered why, now you know. He was a close, personal friend of the Crowell family. Sherman passed in 2012.

|

|

Sunday |

|

|

|

By 0900 Sunday morning, the track crew was back at it.

|

|

|

|

Though the hard work had already been accomplished, some leveling and gauging remained to be done.

|

|

|

|

Gavin learns the art of driving spikes with a maul.

|

|

|

|

Makala (new volunteer) didn't shy away from working hard. She's a welcome addition to our band of brothers/sisters.

|

|

|

|

Uncle Pete came by to say hi with a couple toots.

|

|

|

|

We often wonder what the UP crews think of our humble efforts.

|

|

|

|

DONE!

|

|

|

|

The Crew: Wimbley - Jacques - Makala - Gavin - Everett - Joe Not pictured: Mike - Glen - Jason (behind the camera)

|

|

|

|

Everett ran M-4 over the repaired stretch while several of us gave a roll-by.

|

|

|

|

|

|

|

|

Jacques ...Or is it the Long Leaf Sasquatch?

|

|

|

|

Everett reported that the track was perfectly smooth and the line-side inspectors saw no defects.

|

|

|

|

M-4 took the crew up the hill to Lueck's Loft to put in some spikes while Jason took the tractor around to the same spot over an access road.

|

|

|

|

M-4 departs

|

|

|

|

Long Leaf Road crossing

|

|

|

|

The next location that needed some work was near Lueck's Loft

|

|

|

|

Jacques tries to prove he's level.

|

|

|

|

The security crew deployed to protect the track crew from zombies.

|

|

|

|

Jacques drives home a few more spikes

|

|

|

|

|

|

|

|

There aren't many photos of Jason because he's taking most of the photos. So, here he is with son, Noah.

|

|

|

|

Many zombie hordes were repelled this weekend by Noah and Joe Jr.

|

|

|

|

Fixing a few more spikes near the Engine House.

|

|

|

|

Cody & Casey conducted more testing with M-22

|

|

|

|

Joe & Everett inspect M-2 prior to Joe repairing the wiring for the back-up light.

|

|

|

|

|

|

|

|

Wimbley supervises as Gavin grinds down the brackets that held the skirts.

|

|

|

|

M-22 & M-2 get to know each other as the volunteers dispersed for the weekend... and what an incredible weekend it was!

|