|

Volunteers

1. Mike M.

2. Doug R. (staff)

3. David H. Sr.

4. Tucker B.

5. Larry G. (staff)

Accomplishments

1. Supervised concrete pour and finish in Engine House drop pit

2. Installed interior wall panels in Naval Stores building

3. Inspected artifacts and historic equipment north of Engine House

4. Drained moisture from air tanks and air lines in Engine House and

Machine Shop

5. Removed burned S2 speeder from dense brush and placed on pad for

inspection

6. Located pile of 45 lb. rail near Meridian Bypass line, along with

other useable rail in the nearby area

Wednesday

Wednesday was the big day that we had been planning and discussing – it

was time to pour the concrete floor in the Engine House drop pit. Mike

and I had been making all the various phone calls, emails, final

measurements, and preparation for the pour. With an excellent

recommendation from David Hearne Sr., a good concrete finisher and

concrete company was secured for the job. Mike met the finisher at the

museum earlier in the week to size up the project, and after a phone

call with the concrete company, Wednesday January 12th would be the pour

day. Doug and Larry met Mike and the concrete team at the museum and

supervised the well-executed pour. The metal keyways and stakes

installed at the December volunteer weekend worked perfectly and with

about a yard of concrete remaining, a portion was used to lessen the

steep grade on the road going up to the Planer Mill.

Getting the concrete finally poured is a big accomplishment and will go

a long way in ensuring that the rebuild of the drop pit will see many,

many years of years to the museum. Thank you to all our staff and

volunteers that helped make this happen! We are getting close to the

finish line on this project!

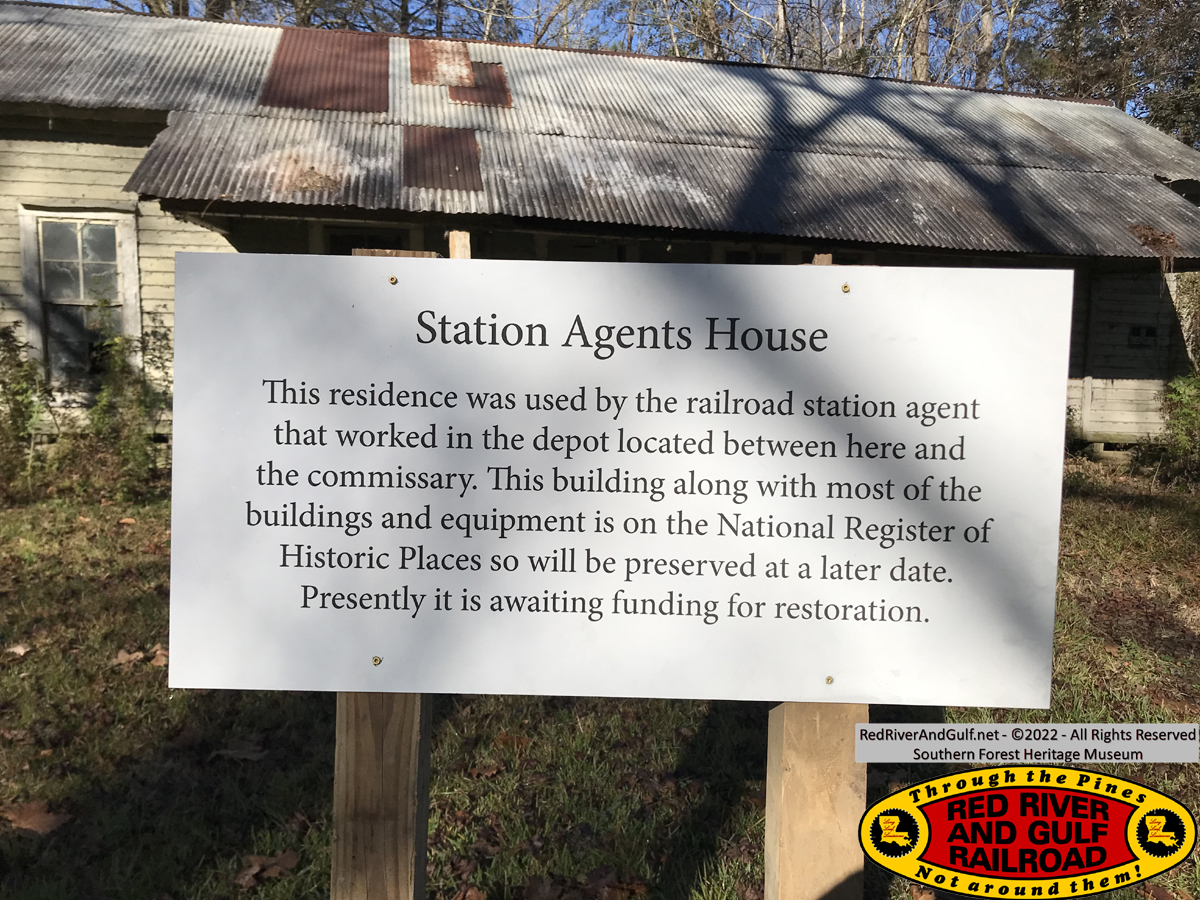

I’d also like to note the new sign in front of the Station Agent’s

house. Thank you to Chuck Lind for the sign! Its good to see the

building get the recognition it deserves.

Thursday

On Thursday morning, Doug and I helped Mike with installing interior

wall boards in the Naval Stores building. Mike had the tools and the

boards laid out already, so Doug and I were working under Mike’s expert

supervision placing the boards into position, making measurements,

assisting with the cuts, the gluing, and the nailing. This project is

also nearing completion, so any help that can be offered, no matter how

small, will help expedite this project’s completion.

After finishing the boards, with David joining us, Mike, Doug, David,

and I inspected the poured concrete. The pour had hardened, and Mike

took the first celebratory walk across it. We discussed the next steps

in securing the timbers for the walls and we are moving now to quickly

continue the rebuild. After the drop pit discussion, we took some time

to inspect the car knocker shed lead track and the equipment north of

the Engine House, including the tractor near lead track #2, the fuel

tanks in the area, the burned S2, the old pickup truck near the tractor,

the various equipment around the camping area, and some potential plans

for said equipment and area.

Returning to the Machine Shop, Mike and I viewed the progress on the

Heisler and discussed the next steps in its restoration. As we discussed

this, Doug and David checked the air tanks and air lines near the fire

whistle in the Engine House. David opened the drain valves and for the

next 15 minutes, water continuously drained out the tanks. The tanks and

lines certainly needed some attention! David checked all the airlines,

blew out moisture as necessary, checked the air compressor in the

Machine Shop for moisture, however, the whistle wouldn’t blow. It may

have a bad seal as we could hear a large air leak up top. Air pressure

was building in the system, but this area will take more attention in

the future.

In the afternoon, we turned our attention to the area north of the

Engine House. David, armed with his chainsaw and loppers, and yours

truly with a cordless hedger, declared war on all the vegetation north

of the Engine House. The effort was very successful, clearing debris,

brush, vines, small trees, bushes, and various scrap map metal along the

various tracks in the area, exposing the equipment we’d like to

relocate, and improving visibility. You can now see and walk through

from the Engine House north end up through the car knocker shed lead

track. This built upon prior efforts by Steve Benson and I clearing the

large fallen trees from this track in November 2019. We plan to increase

our herbicide spraying frequency in this area to keep the vegetation at

bay. In the area in and around the Engine House, the Engine House lead

tracks, around engine 400 and the Clyde Skidder, and around the car

knocker shed lead track are all areas we intended to clear more and more

vegetation from to push back the brush line that has greatly encroached

upon these areas in the past few years.

For last bit of the day, we cut brush and used the tractor with chains

to pull out the burned S2 from the dense vegetation. We relocated it to

the sawmill pad temporarily for inspection. It’s the first time I’ve

seen it clearly and it is indeed in very, very rough shape. Plan is to

inspect, document, and relocate it to a well-suited spot on the museum

grounds. After moving the burned S2, we set out to locate a pile of

45-pound rail near the Meridian Bypass Line. We did determine the exact

location of the pile and came across more equipment piles and more rail

as we went. This includes two side-by-side links of 4 to 5 to 6 rails

each, joined together, 60 pounds, seemingly pushed off the Meridian

Bypass with a dozer. It looks to be about 10 to 12 sticks of rail total,

accessible by tractor. All these efforts are to bring clarity to what

exactly is “out in the woods” on the museum grounds and the rail will be

needed for future rail projects.

Thank you to everyone for a very successful two days. We hope to see you

at the museum soon!

-Tucker "Who Dat" Baker

RR&G Road Master

|

|

Volunteers

1. Mike M.

2. Wimbley

3. Glen A.

4. Clint

5. Doug R.

6. Tucker

7. Everett

Accomplishments

1. New tie inserted and spiked under switch for Engine House track #1

2. Machinery pulled from scrap pile and brought to Machine Shop for

evaluation and restoration

3. Old fuel tank and other equipment near Engine House track #2

relocated

4. Organized Engine House

5. Unloaded and stacked new pit timbers in Engine House

Friday

After the executive committee meeting, several of us took time to

discuss some long-term plans and objectives for our historic railroad

equipment at the museum, including the McGifferts, the Clyde Skidder,

the locomotives, and the equipment at Sandersville and Longleaf

Junction. The goal was move from ideas and goals and to start nailing

down methods, details, and specifics. We are excited for the

opportunities and the challenges before us in the future.

That afternoon, Everett and I set about installing a new tie underneath

the switch for Engine House track #1. Fortunately, there was little dirt

in this area and mostly pine straw and leaves, so inserting the tie was

smooth and simple. With several swings of hammers and a spike maul,

several spikes were hammered in, and the switch was in much better

shape. This was perhaps one of the easiest tie-and-spiking jobs we’ve

done so far. Everett also dropped off the track gauge he had reworked

with fresh lumber and fresh dimension markings, keeping our track tools

in tip-top shape. We also had placed some 2x4s up at the finished lumber

shed for the new drop pit timbers to be stacked on, but fortunately, a

plan came together on Saturday to offload the timbers up at the Engine

House.

Saturday

Despite temperatures hovering at freezing, I cranked up the tractor,

warmed it up gradually, and began the clean-up runs to the dumpster. All

the garbage cans at the Engine House, Machine Shop, and car knockers

shed were emptied into the dumpster. Additionally, several pieces of

rotten wood outside the Engine House were hauled off for disposal.

Later that morning, Glen and Wimbley arrived with Glen’s tractor and

Clint arrived shortly thereafter. Using the backhoe attachment on his

tractor, Glen retrieved a very heavy piece of machinery from the scrap

pile near locomotive #400 and brought it to the Machine Shop for

evaluation and restoration. Also using the tractor and chains, the old

fuel tank near Engine House track #2 was removed and relocated to the

sawmill pad. A tree root had grown over the tank braces and vegetation

had overtaken the area, especially during the summer. Our goals include

removing the trees, brush, and vegetation in this area in order to

relocate some of the equipment in this area, to improve visibility, and

to improve safe working areas around the tracks.

In the afternoon came the expected delivery of our new drop pit timbers

from Natchitoches Wood Preserving. There are 12”x12”x16’ and treated.

With a planned vapor barrier and a concrete foundation already poured,

we hope that these timbers and the new pit will last for decades to

come. After setting down some boards to stack the timbers on, Glen

unloaded the timbers from the gooseneck trailer using a front-end

forklift attachment on his tractor. The whole process went very

smoothly, and we now have the big materials for the drop pit rebuild

staged right next to the pit in the Engine House. With this major task

completed, Glen used his tractor to relocate an old, very large, and

very heavy fire extinguisher that had been pulled from the brush last

year down to the take-down shed to join a fellow fire extinguisher

already on display with wheel and tracked logging equipment.

Thank you to Glen for providing his tractor and equipment operator

skills this weekend. Thank you to all our volunteers and museum staff

that made our plans go off without a single hitch!

-Tucker "Who Dat" Baker

RR&G Road Master

|

|

Volunteers (Saturday)

Mike M

Mike B

David H.

Glen

Wimbley

Andrew

Angela

Dwayne

Jacques

Blake

Clint

Carson

Daniel L

Saturday

The day started early as Angela, Andrew and new volunteer Dwayne all

arrived before 8 am. By 8:30, those three and Everett had gotten both

the M-8 and the M-2 running and were starting to switch out the work

equipment to open up Engine House track 1 for moving Heisler #3 and the

tender from 2-6-0 #204. Gerald came up and moved the M-4 to the loop in

case it was needed, and Wimbley, Carson and Clint moved the M-2 over to

the main line beside the Engine House. Andrew and Dwayne then moved the

M-8, plus the sprayer and a flat to Engine House track #2. Wimbley,

Carson and Clint then moved the M-2 back on to track #1 and made up a

train of the rest of the equipment including the tie crane, two flats

and the large flat car, and brought it out and set it on the main line.

David and Glen with their tractors then pulled out Heisler #3 from track

#1 and set it on the main at the crossing in front of the Engine House.

Then they went back for the tender and pulled it out far enough that #3

could clear the switch for Engine House track #1 so that it could go

back in the Machine Shop. #3 still has a tendency to want to pick the

switch points for Engine House track #1, so that going through that

switch took some time. Everyone pitched in on this operation until #3

was safely on its way into the Machine Shop.

At this point, Blake and Everett patched together every chain that they

could find so that Glen could use his tractor to move the tender down

the main past the switch for Engine House track #1.

Once Glen could latch on to the tender with a shorter chain, Everett,

Andrew and Dwayne moved the M-2 and its work train down and switched it

on to the track headed down the switchback past the #400 so that the

tender could go by on its way to the storage track. During this move, it

was found that the switch back track was a bit out of gauge and the long

flat decided to leave the track. With the help of Glen’s tractor and

Glen, it was quickly rerailed and the process of moving the tender to

the storage track continued. Finally the tender was successfully stored

in the storage track. All of the work equipment was then switched around

to properly position it on track #1 in the Engine House at which time

everyone went to beans.

After lunch it was decided to remove the pit rails so that would

facilitate moving the timbers into the pit. Andrew loosened most of the

joint bar bolts, but several needed the assistance of David and the

torch. Wimbley, Carson, Dwayne, Clint and Dennis pulled all of the

spikes and prepared to remove the rails. Glen and his tractor lifted up

the up hill rail and David placed it carefully out of the way. It was

decided to try and remove both joints of the down hill rail of track #2

and that required the use of Glen’s tractor on one end and David on the

museum tractor on the other. Once the rail was on the side of the pit,

David pulled it carefully beside the other one, and he and Glen shoved

it into position out of the way.

Mike, Mike and Angela removed the steam delivery and exhaust pipes on #3

in the afternoon.

While all of this was going on we did a controlled burn on the brush on

the storage track. David supervised some of this and at other times it

was carefully watched over by most of the volunteers at one time or

another.

Everyone got together to re-gauge the bad spot on the switchback track

and spike it into place. At that point, a very tired bunch of volunteers

called it a day, cleaned up and put everything away and closed the

doors.

Sunday

Angela, Everett, Jacques, Andrew, Dwayne, Glen, Wimbley and Mike B

worked Sunday Morning, and Glen, Wimbley and Jacques worked the

afternoon as well.

Mike B was working on #3 continuing disassembly of the locomotive.

Glen, Jacques and Wimbley dedicated themselves to the completion of the

overhaul of the all-terrain fork lift. By the end of the day they had it

almost all together and had it running except for a few hoses left to

install.

Angela, Andrew, Dwayne and Everett attacked the problem switch that

leads to Engine House track #1. The initial plan had been to swap out

the troublesome switch point, but after some study, they were able to

adjust the point to where it should work properly.

-Everett Lueck

RR&G General Manager

|