|

|

|

Work Session June 19, 2021

To join the fun, contact the railroad at: Work-Session @ RedRiverAndGulf.net (no spaces)

|

|

Team:

Mike B.

Noah R.

- Drop Pit Demolition Complete

Thank You's:

Good New

Department:

-Tucker Baker

|

|

|

|

With the help of Glen and his backhoe, the final demolition of the Drop Pit began in earnest Friday afternoon.

|

|

|

|

What was impossible to do by hand, was made short-work with the heavy machinery. Thank you, Glen!

|

|

|

|

|

|

|

|

To our surprise, two drainage pipes were located under the floor. We believe these are still partially operable.

|

|

|

|

|

|

Saturday morning, Clint grinds off nails from the floor boards removed from the bottom of the Pit. These will be re-used.

|

|

|

|

Continuing the clean-up

|

|

|

|

Mike and Mike de-crib the M4 so that it can moved further inside the Engine House.

|

|

|

|

|

|

|

|

|

|

|

|

Noah shovels out mud from the Pit.

|

|

|

|

|

|

|

|

Andrew, Jason, and Noah

|

|

|

|

Wimbley, Andrew, Jason, and Noah finish the clean-out of the Pit

|

|

|

|

Glen uses the backhoe to load the bucket on the tractor, saving time and energy.

|

|

|

|

|

|

|

|

Glen pulls M4 further into the Engine House

|

|

Everett found a concrete wing at the south end of the Pit. We hope to restore this section soon.

|

|

|

|

Angela and Cling cut scrap lumber to make more Pit covers.

|

|

|

|

Mike, Mike, and Glen re-jack and crib the M4 so the front truck can be removed.

|

|

|

|

Installing gauge bars in the Pit

|

|

|

|

Everett and Angela

|

|

Done

|

|

|

|

Mike and Glen jack and crib M4

|

|

|

|

Putting the Pit covers back on

|

|

|

|

Post-lunch discussion of objectives. Congratulations to Everett on the announcement that he'll soon be a GREAT GRANDFATHER!

|

|

|

|

Finishing the cribbing of M4

|

|

|

|

Pulling out the front truck

|

|

|

|

|

|

|

|

|

|

|

|

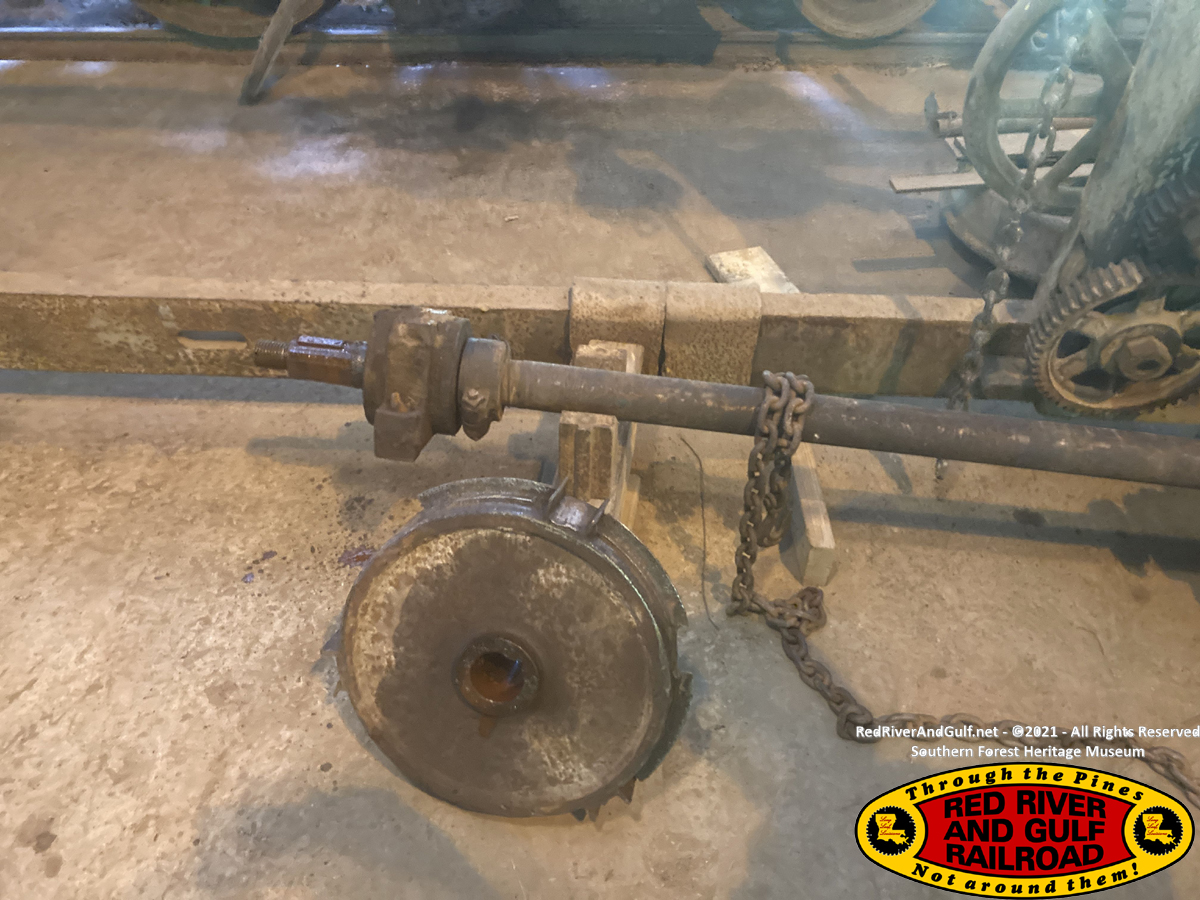

Loosing the nut on the axle This was the easy part...

|

|

|

|

The wheel was frozen to the axle. So, Mike Miller came up with the plan to use the wheel press and a 50 ton jack to get it off.

|

|

|

|

|

|

|

|

We used the A-frame in the Engine House to partially disassemble the truck frame to get the axle off.

|

|

|

|

|

|

|

|

While the truck frame was being disassembled, Tucker, Andrew, and Noah did some much-needed brush trimming.

|

|

|

|

After an hour, the axle was free.

|

|

|

|

Andrew and Tucker continue the brush clearing. It sure looked better when they were done.

|

|

|

|

Clint

|

|

|

|

Andrew

|

|

|

|

Using the wheel press to get the wheel off of the axle

|

|

|

|

|

|

|

|

The Wheel Press isn't operational, so a 50 ton jack was used instead. Simple and ingenious!

|

|

|

|

|

|

|

|

With a bang, the wheel was free!

|

|

|

|

Andrew picks up a confused visitor

|

|

|

|

While waiting for everyone to take a shower before dinner, we spent some time with the Night Security & Pest Control Crew.

|

|

Everett and Muggins

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sunday morning, Tucker runs M8 and a flatcar out to the pad to load up ties.

|

|

|

|

Andrew, Noah, Angela, and Jason rounded out the crew.

|

|

|

|

RR&G #106 patiently awaits the day when a fire is lit in her belly.

|

|

|

|

Tucker uses the fork lift to load ties

|

|

|

|

|

|

|

|

|

|

|

|

Andrew, Noah, and Angela

|

|

|

|

Andrews run M8 up the hill to drop ties

|

|

|

|

Ties are placed in preparation for major track work in the near future.

|

|

|

|

Jason unloads ties near Main Line Jct.

|

|

|

|

|

|

|

|

The new & official RR&G Office

|

|

|

|

Everett hand-lettered the new sign.

|