|

|

|

Work Session December 4-6, 2020

To join the fun, contact the railroad at: WorkSession @ RedRiverAndGulf.net (no spaces)

|

|

Team: Wimbley

Doug (SFHM Staff) David Hearne David Hamilton Tucker Everett Jason

Summary:

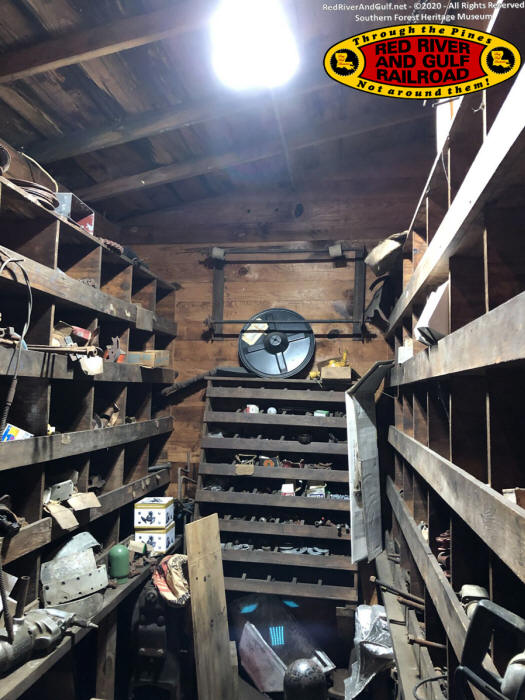

Accomplishments: - Jason single-handedly installed upgraded and wide-reaching interior illumination systems in both engine house tool rooms

with zero safety

incidents or cost overruns while increasing interior illumination by

800%

- Drop side flatcar now

returned to service

by hand crank switch points sorted and stored - Wimbley and Glen also brought replacement builders plates for the 202. - Jason moved the open gallery car to let a very excited brother and sister from Monroe operate the handcar and they helped Everett re-position equipment while the rail sorting was going on. - Everett repaired the switch to the #1 engine house track which was damaged by a fallen tree during Laura.

- Another drawbar was also

fabricated to use with the push-car trains

Friday

-Tucker Baker Friday |

|

New 8000 lumen lights in the Tool Rooms! It's so bright in there that we were finally able to locate the keys to the 106!

|

|

|

|

Tucker greases the bearings on the Bridge Crane (Ichabod)

|

|

|

|

Cleaning the windows on M-2

|

|

|

|

|

|

|

|

|

|

|

|

Cutting off stubborn bolts on the Bridge Crane (Ichabod). We removed all of the components of the hydraulic system that we aren't going to use.

|

|

|

|

Jason tows the tender for Two-Ought-Two out of the Machine Shop so that we could get the Drop-Side Flatcar out.

|

|

|

|

|

|

|

|

"Easy does it..."

|

|

|

|

|

|

|

|

Moving the Drop-Side Flat (The Horseman) under the lift.

|

|

|

|

Up she goes!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

She's up and ready for new wheels and axles.

|

|

|

|

Putting the Tender back in the Machine Shop

|

|

|

|

|

|

|

|

Tucker found a bird nest from atop the Tender.

|

|

|

|

|

|

|

|

Two-Ought-Two

|

|

|

|

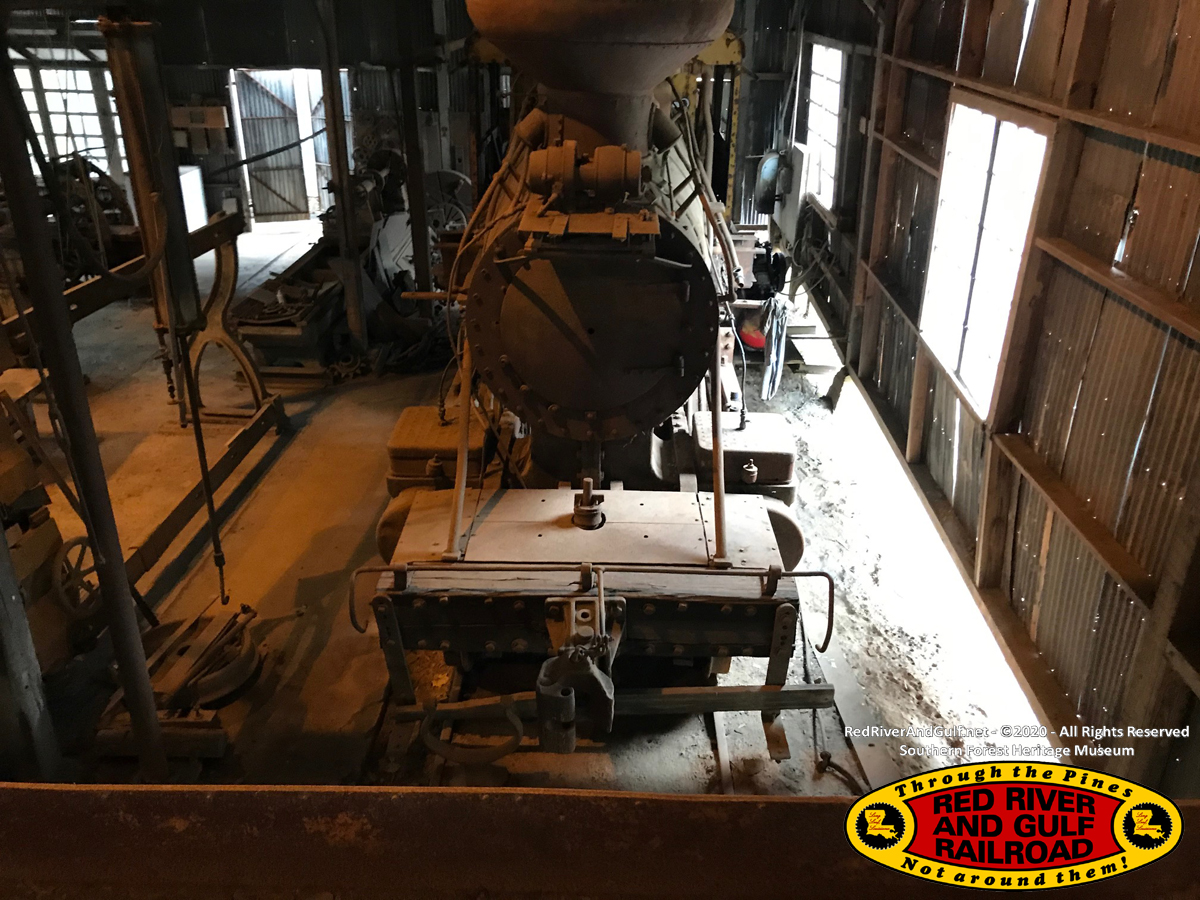

New view of the belt drive in the Machine Shop

|

|

|

|

Jason backs the tractor out

|

|

|

|

Tucker sweeps off the Tender

|

|

|

|

SFHM Director Doug looks on as Everett adjusts the cable on the Bridge Crane (Ichabod).

|

|

|

|

The view from the Depot

|

|

|

|

Long-time volunteer (and one of our heroes), David Hamilton, spent an hour discussing the restoration and how to operate the McGiffert.

|

|

|

|

Old wheels and axles have been removed.

|

|

|

|

|

|

Saturday |

|

|

|

Long Leaf was socked-in with fog Saturday morning.

|

|

|

|

The Saw Mill

|

|

|

|

|

|

|

|

Remnants of the blow pipe used to move sawdust from the Saw Mill to the boiler room at the Planer Mill.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RR&G Loop, near the Saw Mill.

|

|

|

|

McGiffert and Machine Shop

|

|

|

|

Car Shop

|

|

|

|

106 waits quietly in the Car Shop for her day to return to service.

|

|

|

|

|

|

|

|

McGiffert

|

|

|

|

Main Line Junction

|

|

|

|

M4 looks north up the main from the Engine House

|

|

|

|

Looking north towards Long Leaf Junction

|

|

|

|

Engine House

|

|

|

|

|

|

|

|

Long Leaf Loop

|

|

|

|

|

|

|

|

|

|

|

|

With temps in the upper 30's, Tucker lit a fire in the Engine House "heater." This may be the first fire in there in decades.

|

|

Smoke from "the heater" rolls over the Engine House. Could this be a harbinger of what it is to come?

|

|

|

|

Everett reinforces the steel support on the Drop-Side Flat before we put on the new axles and wheels.

|

|

The fire burned for hours. There is plenty of firewood laying around after the hurricanes and tropical storms this past summer.

|

|

|

|

Securing the new axles on the Horseman.

|

|

|

|

|

|

|

|

Done! Horseman has his new axles & wheels.

|

|

|

|

Seeing smoke waft through the Engine House made us all think about the future...

|

|

|

|

Down she goes...

|

|

|

|

Glen and Wimbley apply grease to Ichabod

|

|

|

|

Dave welds a new crank for Ichabod

|

|

|

|

DONE! Ichabod & Horseman are (mostly) complete and coupled together.

If we're successful in running Halloween trains in 2021, you could see Ichabod pulling Horseman loaded with pumpkins. That's pretty funny!

|

|

|

|

|

|

|

|

Mike unwraps new glass for the cab doors on 106

|

|

|

|

Glen & Wimbley pose on 106

|

|

|

|

Glen cast the new number plate for 106 and it sure looks great!

|

|

|

|

|

|

|

|

Glen installs the glass in the Fireman's side door.

|

|

|

|

|

|

Then the Engineer's side.

|

|

|

|

Working on M-2. She was being stubborn and wouldn't start.

|

|

|

|

Didn't take long for Dave and Everett to get her happy again. Dave single-handed located the short... by shocking himself. THANKS DAVE!

|

|

|

|

Continuing the effort to clean up the Engine House

|

|

|

|

MOW train departs on Track 2. M-2, Ichabod, and Horseman.

|

|

|

|

|

|

|

|

Backing down the Main to "the pad" to test the crane.

|

|

|

|

Up she goes...

|

|

|

|

Everything worked perfectly except for the brake on the lifting cable. It was insufficient to hold the 600lbs rail. We'll adjust it in January.

|

|

|

|

Tucker moves rails between piles. All good 60lbs rail was relocated to a new pile near the Loop Main for easy access.

|

|

|

|

Mike shoves good rail onto the tines of the forklift.

|

|

|

|

Mike drags good rail onto the tines of the forklift.

|

|

|

|

We wrapped things as the sun dipped behind the trees.

|

|

|

|

As the final light of day fades to night...

|

|

|

|

...the crew gathers under the

lights of the RR&G Engine House to discuss dreams that are becoming

plans... and plans that are becoming reality. The future for this old railroad is very bright. |

|

Sunday |

|

|

|

Sunday morning, Everett, Tucker, and Jason drove up to Georgetown, LA to check out a critter that we may want to acquire for the RR&G.

|

|

|

|

We located the beast with no trouble.

|

|

|

|

She's a cute little thing... in an "ugly duckling" sort of way.

|

|

|

|

|

|

|

|

Unfortunately she needs more work than we can provide right now.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This little fella is sitting a short remnant of the old Louisiana Midland Railroad that was used by DJ Railcar Services Inc.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We bid the critter farewell and that ended a VERY successful and productive weekend.

|