|

Team:

David Hearne, Everett Lueck, Mike Miller, Tucker Baker, Doug Rhodes and

James Barnett

Friday:

Tucker Baker and Everett Lueck finished water leak suppression efforts

on the machine shop, sealing up other points of obvious water entry, and

blocking water which was flowing over the coal pile across the coal

deck, down the wall and into the shop. Chuck Lind painted the switch

targets along the machine shop and out into the woods. Only three switch

targets remain to be painted. Tucker and Everett also worked on cleaning

the engine house of wood debris and scrap metal. Doug Rhodes and Jim

Barnett worked with Everett how to move the wireless equipment from the

hotel to provide wireless wi-fi in the commissary.

Saturday:

David Hearne began replacing the old broken electric radiator fan in the

M4, as well as the engine powered fan, with a new, high capacity

electric radiator fan that will suck air through the radiator whether

going backwards or forwards. In the process of doing this, it was

discovered that the radiator is not fastened in the car, and that the

upper radiator hoses were too short, tilting the radiator backwards,

thus inhibiting the air flow as well. David will both get new, proper

length radiator hoses, and build a mounting so that the radiator is

properly and solidly mounted in the car.

Much discussion ensued between all of the volunteers present regarding

the status of the track in the machine shop. The final consensus is that

the rails need to be disconnected, and the area backfilled and graded

with clay based dirt as well as new ties inserted to bring the track up

to level.

All present turned to and leveled the second tilting foundation block on

the side of the machine shop, using concrete block and metal shims to

support and level the block. The wall is still not straight, but it is

solid.

After completing the wall leveling, it was decided to remove the rotting

tie pile behind engine #400, salvage what good ties might be there and

dispose of the rest.

David Hearne on the Forklift and Tucker Baker with the tractor and

trailer disposed of the entire pile behind the locomotive, with help

from the other volunteers present.

David then used the tractor to blade the track behind the #400. We

discovered that one rail (the mill side) was intact all of the way to

the switch, but the other rail had been broken and badly bend behind the

locomotive, so that it will have to be replaced before the engine and

the Clyde Skidder can be moved.

Sunday:

David Hearne continued his work on the M-4 radiator, which he hopes to

complete this week. Everett Lueck salvaged switch parts, inspected

switches by the engine house, and ground rail joints in front of the

engine house.:

PRIOR WORK by Mike and his crew

Mike Miller obtained the services of Ball Crane services to remove the

tank from the short log car which has long been stored in the engine

house. The car had deteriorated to the point where the tank had to be

braced to keep it from rolling off of the car. Mike then chained the car

together and moved it out on to the storage track in front of the engine

house for temporary storage. Mike also moved the tender from the #204 in

the engine house to access materials behind the tender (including the

long removed air pump from engine #202). Just this much has made the

engine house a much more user friendly area.

----

I inspected all of the switches

by the engine house- shop today. I did not go down the line toward

Sandersville, but will do that next visit.

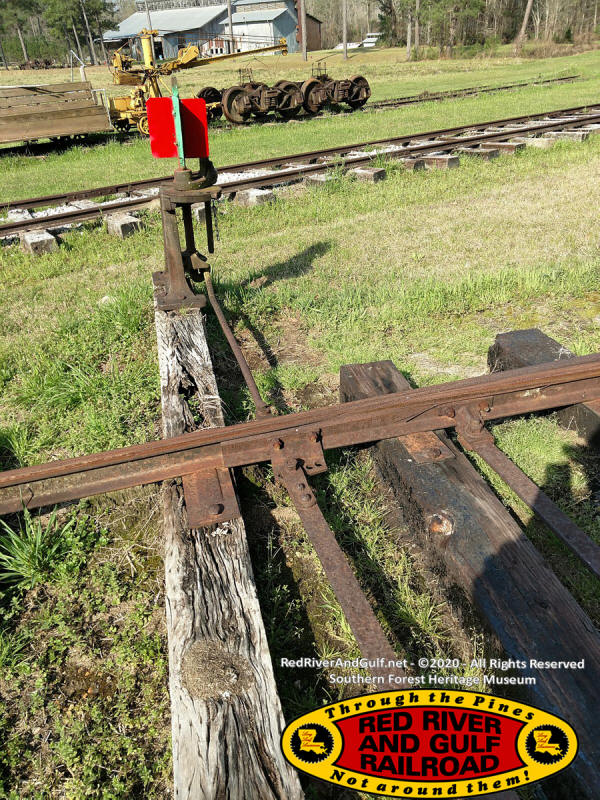

Below are a pair of photographs from two switches, the main line switch

next to the shop, and the switch leading to the 400.

The main line switch is an obvious defect. The switch point leading to

the 400 has some wear but is fully FRA compliant.

Therefore, I propose at a future work session (soon) we remove the

switch point on the mainline switch and replace it with the one from the

400 lead. We can adjust the #1 switch bar accordingly and have a safe

switch that we operate over all of the time. We can also use the bad

point on the 400 lead, as it will NOT be used to move operating trains

over, but only for a storage track once the 400 and the Clyde are out.

We have a #1 switch bar and a #2 switch bar for 400 lead, although we

are missing a casting from one end of the #1 bar that we will have to

obtain or purloin somewhere. at the time that we intend going after the

400 and the Clyde.

-Everett Lueck

RR&G Director

|

_small.jpg)